Specified by Orbit Architects & installed by Cre8 Joinery

When Cre8 Joinery approached Gooding Aluminium (GA) requiring bespoke radiator vent covers for The Emirates Lounge at Stansted Airport, we knew precision would be key. Orbit Architects requested a solution that married aesthetics, functionality and maintainability, and that’s exactly what GA delivered.

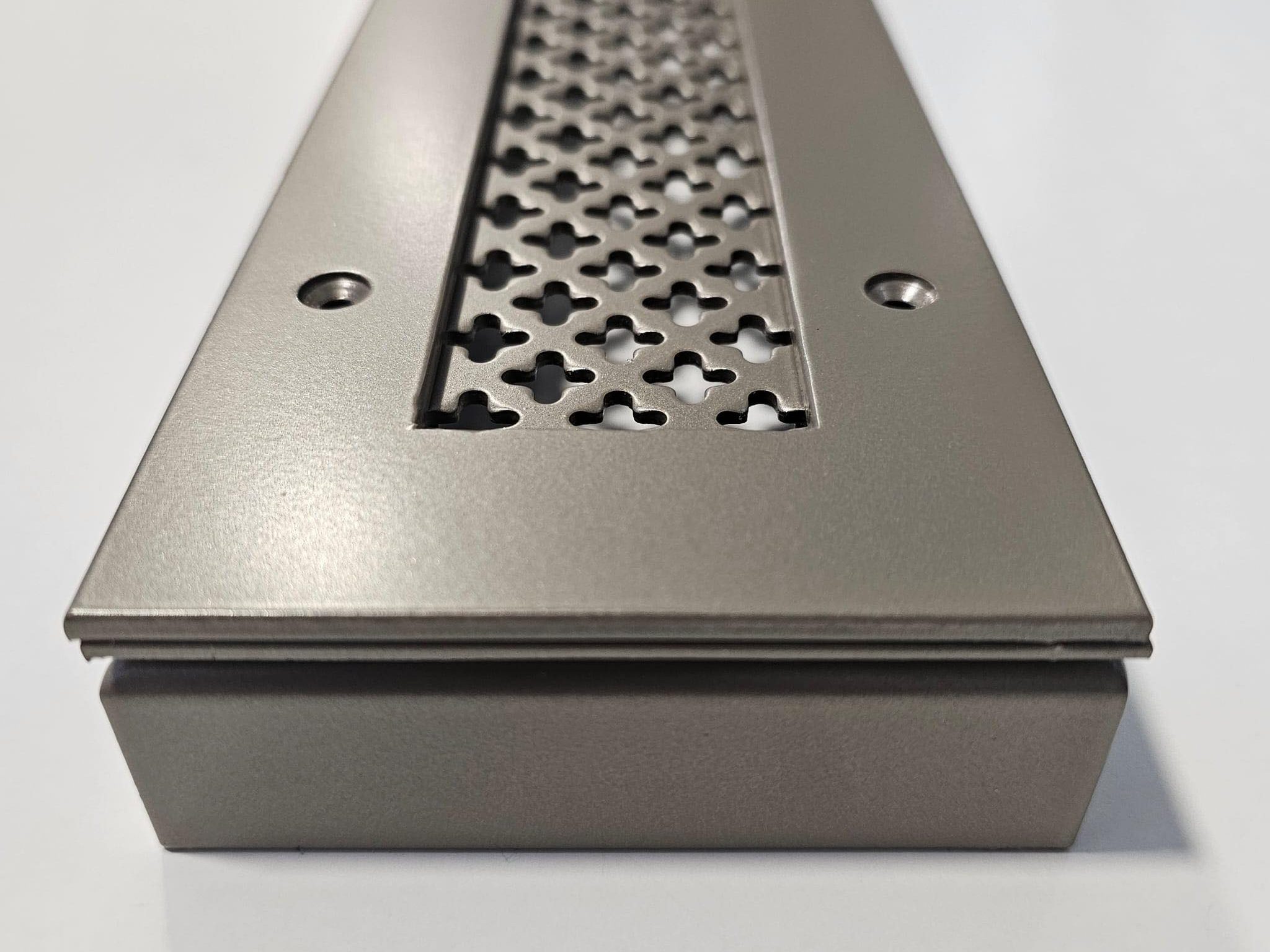

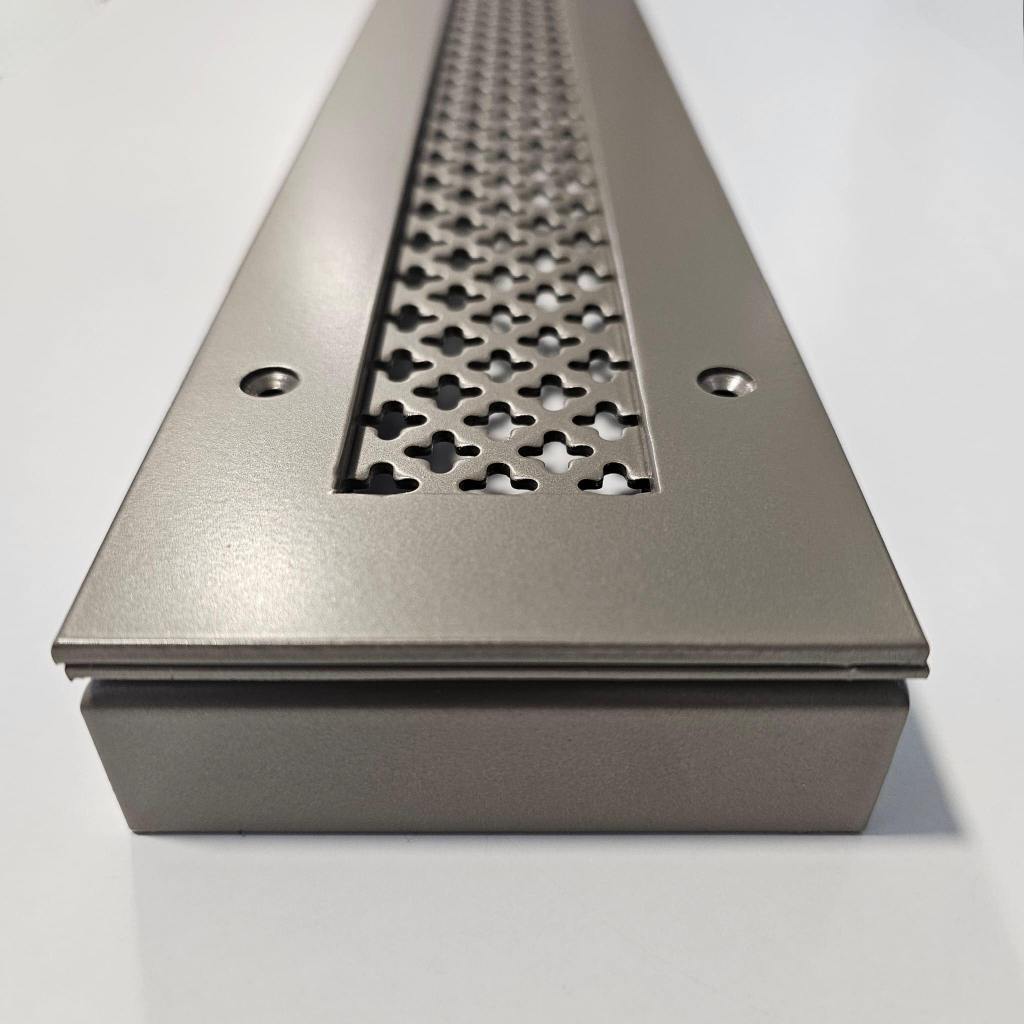

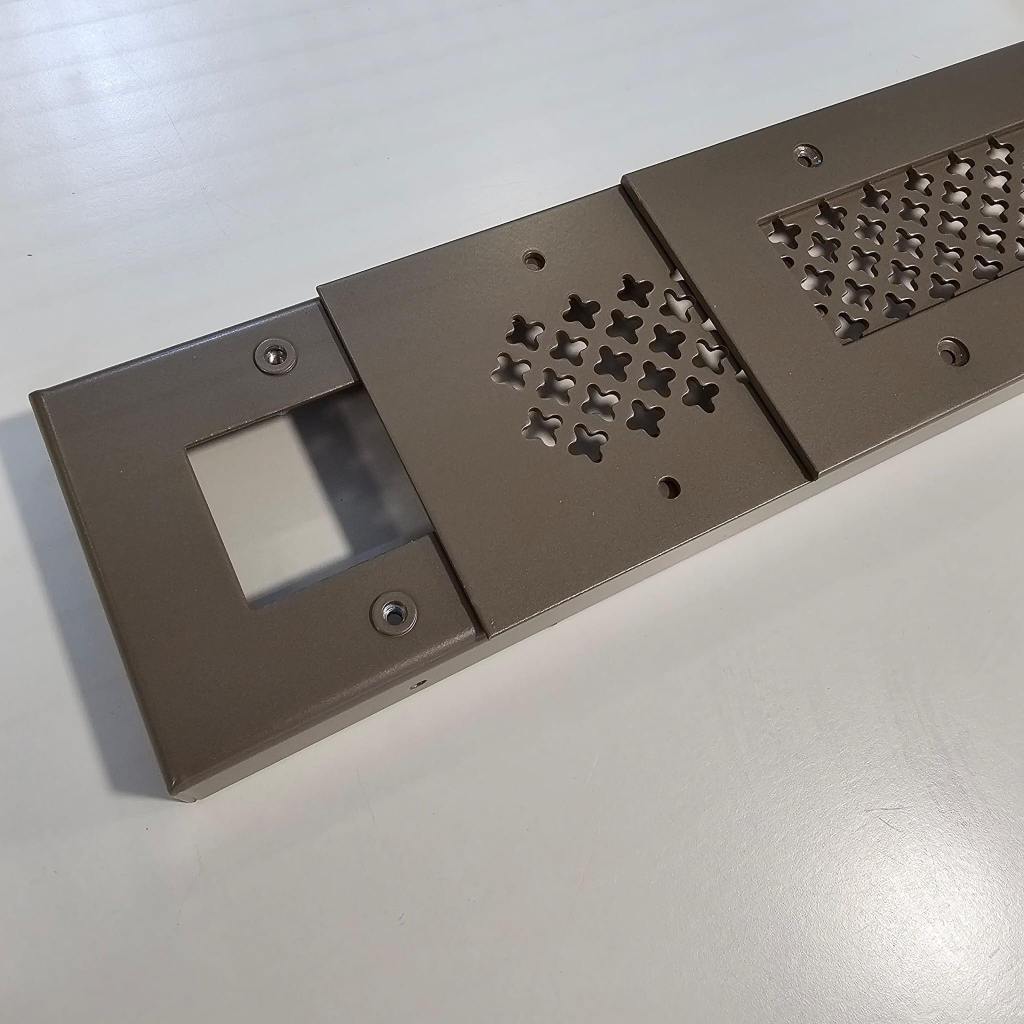

GA produced a three‑part fabricated system of bespoke perforated aluminium removable airflow vent covers, expertly powder coated to a matt pearl‑beige RAL 1035. This design provided a flush‑to‑surface appearance, creating a seamless, elegant finish throughout the lounge.

Why a three‑part system?

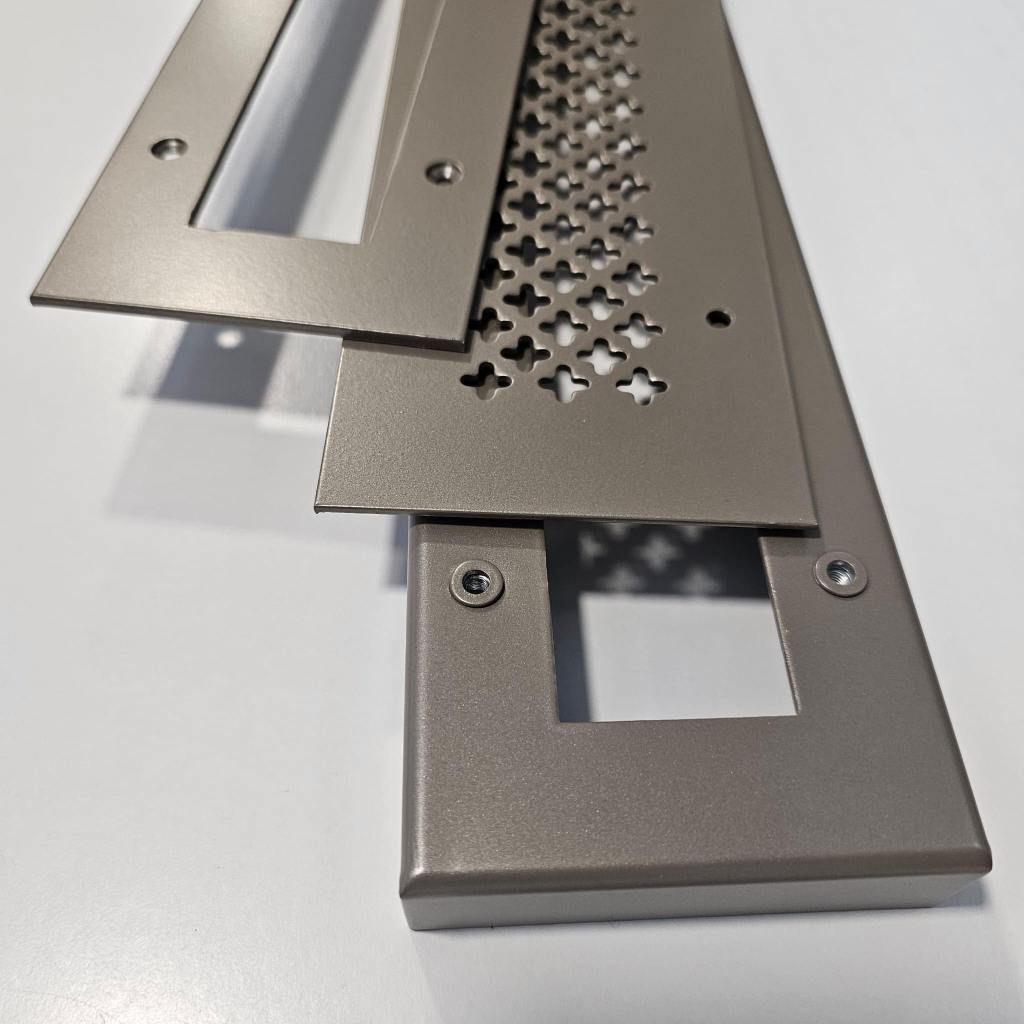

Each panel assembly comprises:

- A 2 mm thick punched and folded aluminium frame, incorporating M5 rivnuts.

- A perforated panel in pattern GA PCL102, complete with precise clearance holes.

- A 3 mm thick surround top cover, featuring countersunk holes for M5 screws.

This modular approach offers three clear benefits:

- Straightforward installation: sections fit directly into existing heater casings.

- Easy removal: any panel can be taken off for future maintenance without needing to dismantle the whole assembly.

- Customisable design: frames and covers can be tailored for fit and airflow requirements.

High‑quality finishes and fabrication

GA’s 5‑Star Processing Service ensures rapid, made‑to‑measure fabrication using a wide range of materials and finishes. For The Emirates Lounge, a powder‑coated finish in RAL 1035 was chosen to match the lounge’s colour palette and resist airport‑style wear and tear.

Alternatively, GA offer anodised, mill (untreated), and satin‑brushed surfaces – perfect for architects seeking different finishes. The powder coat adds added durability and is suited to public‑facing interiors.

Perforated panels: form meets function

The GA PCL102 perforation pattern ensures adequate airflow to radiators while maintaining a polished finish. Pierced aluminium panels provide many benefits:

- Visual appeal: perforated aluminium creates clean sightlines and stylish detailing.

- Airflow efficiency: ensures radiator vents function correctly without obstruction.

- Lightweight construction: aluminium offers structural efficiency yet remains easy to remove.

GA’s standing in bespoke perforated aluminium panel fabrication means designs can include plain borders, bespoke hole patterns, return folds and even curved surfaces. This is ideal for architect‑specifiers requiring unique, functional solutions.

Built for accessibility and ease of maintenance

Airport lounges demand easy maintenance and long‑term reliability. GA’s removable panels mean:

- Ease of access: simply unscrew the top cover to uncover the perforated panel and frame – perfect for routine radiator servicing.

- Future flexibility: damaged or outdated panels can be replaced individually, without replacing the entire assembly.

This modular system supports the operational needs of busy spaces like The Emirates Lounge.

Technical precision & quality assurance

Gooding Aluminium follows BS EN standards for sheet and extruded aluminium, maintaining tolerance and build quality. Combined with ISO 9001:2015 certification, GA’s processes ensure consistent quality from initial specification to final install.

Fixings use M5 rivnuts for secure, long‑lasting joins, while powder‑coated finishes are applied in‑house with strict quality controls to avoid issues like jig‑marking and shading variations.

Project summary

- Product: Three-part bespoke framed perforated aluminium removable airflow sets

- Usage: Radiator airflow vent covers

- Perforation pattern: GA PCL102

- Surface Finish: Powder coated to matt pearl beige RAL 1035

- Material thickness: Frame: 2 mm; Surround: 3 mm

- Fixing system: Flush, countersunk M5 screws

- Location: The Emirates Lounge at Stansted Airport, Essex

- Client: Emirates Airways

- Specifier: Orbit Architects, London SE1

- Contractor: Cre8 Joinery Ltd.

Design keywords

This project demonstrates high‑quality perforated aluminium panels, radiator vent covers, bespoke aluminium vent covers, powder coated finishes, removable airflow panels, and airport lounge interior design. These terms are naturally integrated into the narrative, supporting both search visibility and technical clarity.

Conclusion

The Emirates Lounge installation is further proof of GA’s ability to meet complex design briefs with precision engineering, aesthetic control and practical versatility. By specifying bespoke perforated radiator vent covers, Orbit Architects and Cre8 Joinery created a system that is both elegant and functional – easy to install, maintain and carefully matched to the lounge’s interior scheme.

If you’re working on hospitality, aviation or high‑traffic interior projects, GA’s bespoke radiator and vent cover solutions offer custom‑made aluminium components, rapid fabrication, and finishes ranging from powder coat to satin brush. The Emirates Lounge installation sets a high standard for high‑end interior detailing.

Leave a comment