Online now: Gooding Aluminium’s perforated brochure

Perforated aluminium is a versatile and practical material that offers far more than decorative appeal. With the right design, it delivers acoustic control, visual privacy, airflow, light diffusion and even weight reduction. That’s why perforated sheet is now a staple in UK architecture, interior design and specialist metalwork fabrication.

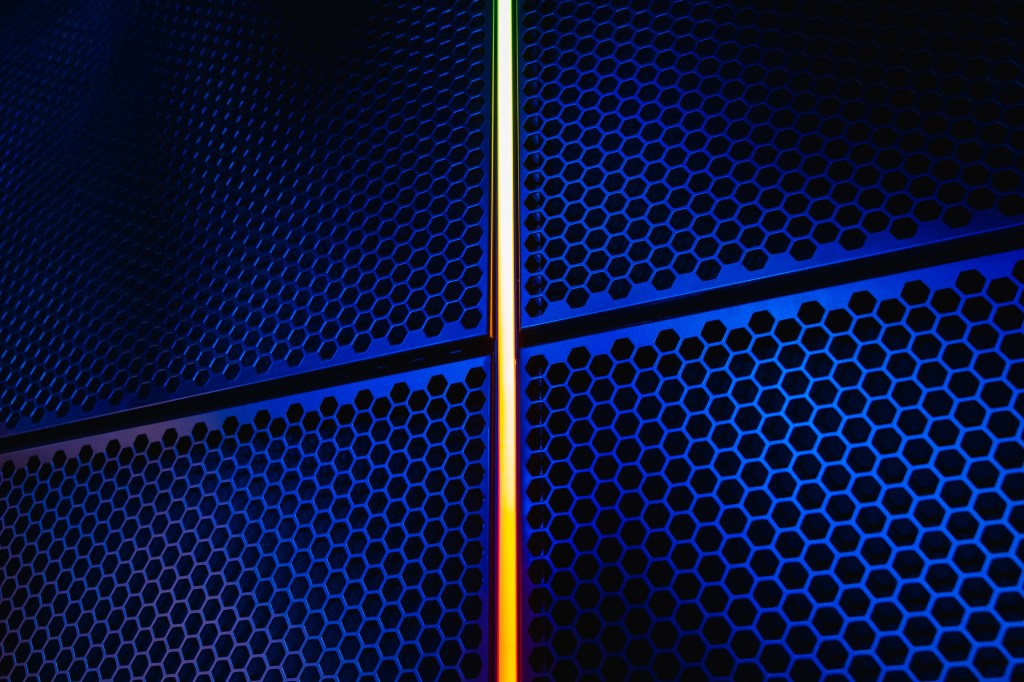

At Gooding Aluminium, our perforated aluminium sheets and bespoke perforated panels have featured in award-winning projects across the UK – from retail installations to large-scale public and cultural buildings like Outernet London, where hexagonal perforations formed part of the acoustic wall cladding solution.

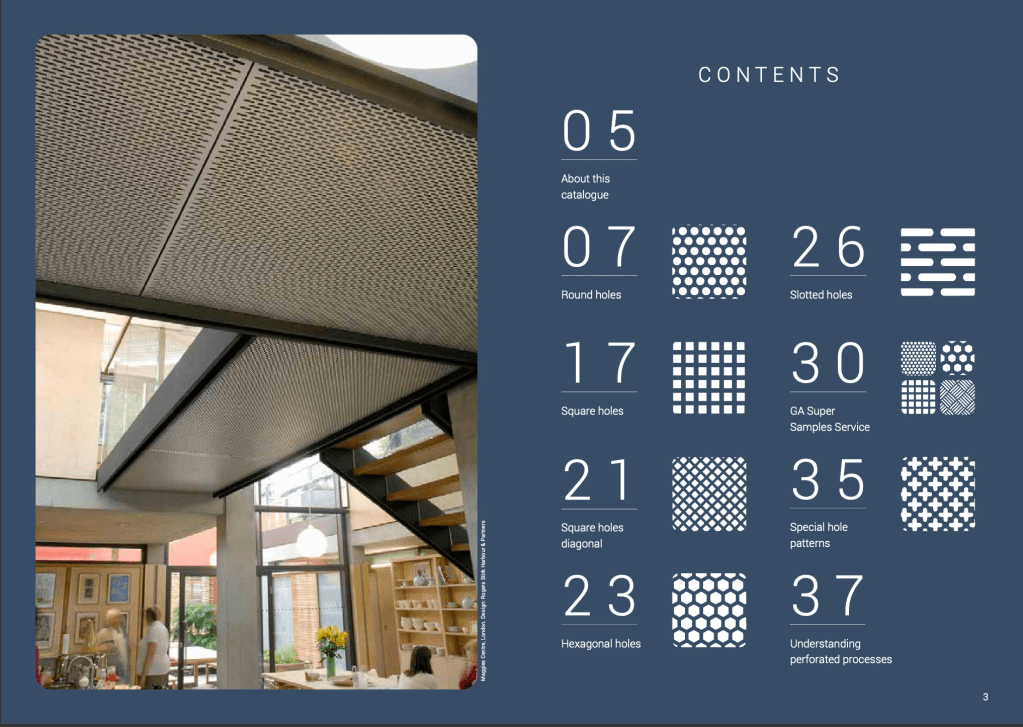

To support designers, specifiers and architects, we’ve just released a new Perforated Sheet Patterns Brochure, showcasing our standard aluminium perforation patterns. Available to view online, this helpful resource also explains the perforating process and how to select the right perforated aluminium sheet or design a bespoke panel using our 5 Star Service.

Why specify perforated aluminium?

From architectural metalwork and interior fit-outs to ceiling panels, cladding and screening, perforated aluminium sheets solve a wide range of practical and design challenges. They are widely used in UK construction and fit-out projects for the following reasons:

- Acoustic absorption

- Light diffusion and transparency

- Weight reduction without compromising strength

- Airflow and ventilation

- Screening and privacy

- Decorative detailing with visual rhythm

- Security barriers in commercial environments.

In short, aluminium perforated sheet offers both performance and elegance, which is why it has become such a popular choice across sectors from workplace and retail to education, culture and residential.

Understanding perforated aluminium

Perforating aluminium is a precise and highly technical process that can be tailored to meet project-specific requirements. At Gooding Aluminium, we offer a wide range of standard perforated sheets, and also fabricate specially perforated aluminium panels to bespoke specifications – often with short lead times.

When designing or specifying perforated metalwork, a few technical principles are worth knowing.

Blank areas/margins can be incorporated into specially perforated panels. Always check with our technical personnel to ensure the suitability of your perforated / plain layout before committing to specification.

Broken edges (absence of border margins) are not supplied by GA on standard stock size or specially perforated panels. Shearing to size from stock panels may result in broken edges.

Cleanliness on mill finish materials may vary from a relatively dry finish to a light residue of water soluble lubricant (necessary for the perforating process). It is advisable to arrange for mill finish materials to be wiped over on site, after installation.

End margins with staggered hole arrangements can result in either a finished or unfinished pattern at each end of the work piece.

Flatness in perforated sheets is never absolute. Factors including overall panel size, the ratio of perforated to plain areas, the % open area, material thickness, all affect the degree of distortion. Our technologically-advanced production methods minimise these difficulties and help to produce commercially and visually acceptable degrees of flatness.

Hole size relative to material thickness is an important consideration. Avoid approaching a 1:1 ratio, i.e. 3.5mm hole dia in 3mm thickness. Instances of similar hole size and material thickness result in a less than satisfactory appearance and possibly tool breakage, causing production delays and other complications.

Ideal perforating material thicknesses from a quality processing point of view are between 1 and 3mm.

Short lead times can be provided from the selection of stock sheet configurations. Increased rigidity can be designed into a perforated panel by increasing material thickness, incorporating a plain border, and / or a surround frame.

Material costs can be minimised by selecting from our range of standard hole size / shape configurations. Specially perforated panels can be produced economically and quickly. Bespoke hole layouts can involve longer lead times and new tooling charges.

Missing or imperfect hole shapes result from broken or damaged punches. This is not an unusual occurrence when perforating large numbers of small holes. It is standard industry practice to supply an acceptable % spoilage factor. GA policy aims to provide as near possible 100% complete perforations.

When specifying perforated ‘specials’ please confer with our Technical Sales Department before finalising a design. Various min / max production ratios apply to hole size, bridge distance, material thickness, end and side margins etc, which need to be observed to avoid possible material distortion and or fracture.

‘Open area’ in many applications, is of critical importance for reasons of air flow, screening etc. Please refer to the percentage open areas given for each GA standard pattern.

Quoted percentage open areas given in our website relate to the ratio of the total area of the holes to the area of perforated sheet, excluding the unperforated margins.

Plain margins on pre-punched sheets might or will be lost once sheared to size.

Polythene film on the punch face side only, is applied to help protect the material surface from the rigours of the perforating process.

Production tolerances for bespoke items incorporating perforations are less precise than for plain sheet working. Please refer to our GA5* Processing Standard for details.

Round holes with a 60 ̊ staggered pattern, are the most common hole arrangement, this is due to the inherent strength and wide range of available open areas.

Side margins should ideally be kept to an even dimension of less than 80mm, this helps to reduce surface camber and distortion.

Small quantities of ‘specials’ can often be economically and quickly produced by GA. Our bespoke software accurately calculates best use of materials and punching arrangements.

Standard size panels are shown with nominal overall dimensions, these can vary slightly depending on the necessity to ‘square’ sheets before perforating commences, and the degree of material ‘stretch’ during processing. Stock sheets are normally supplied with a minimum border margin.

The two sides of a perforated surface are not the same. The punch face side is where the punch enters the material and the burr side indicates the punch exit on the underside.

Visible faces should be indicated on unsymmetrical panels and fabrications as the punch face side is superior to the burr (underside). It is advisable to avoid specifying mill or anodised finishes when both sides of the sheet are to be closely viewed. Powder coating minimising these difficulties.

Square holes provide good visibility and air flow while providing decorative cover. Staggered patterns for rounds and squares will normally be the short dimension of the sheet. The straight row of holes is usually parallel to the sheet length.

Precision and performance

Our 5 Star Perforating Service accurately and rapidly produces custom perforated panels in aluminium, with a variety of design options:

- Plain border margins or shaped blank areas

- Return folds, folded edges or cut-outs

- Fixing holes in non-perforated zones

- Pattern matching for aesthetic continuity

- Curved or rolled perforated panels.

All fabrication is completed in-house, ensuring tight quality control and a consistent finish.

Choosing the right perforated aluminium sheet

Our Perforated Sheet Patterns Brochure includes all standard perforation styles we keep in stock – with variations in:

- Hole shape (round, square, hexagonal, slotted)

- Hole size (ranging from 1.3mm to 40mm+)

- Open area (typically from 8% up to 59%)

- Sheet thickness (1.2mm, 2.0mm, and 3.0mm standard)

- Panel size (2000 x 1000mm or 2500 x 1250mm).

These ready-made configurations support quick turnaround and value-driven selection. We also provide free samples to help you choose the most suitable style.

High-performance architectural metalwork

Perforated aluminium is a natural choice for UK architectural metalwork, particularly in:

- Interior wall cladding systems

- Ceiling panels and baffles

- Retail displays and facades

- Ventilation and radiator grilles

- Column casings and lighting diffusers

- Balustrades and privacy screens.

You can see examples in our Perforated Sheet brochure and use our Build a Spec tool on the GA website to assemble your own made-to-measure product selection.

Fast delivery and expert support

Gooding Aluminium stocks a wide range of perforated aluminium sheets for immediate dispatch and delivers nationwide. If your project needs a bespoke solution, our fabrication team can assist with quick-turnaround production, technical advice and finish recommendations.

To discuss a current project, or to request a copy of the Perforated Sheet Patterns Brochure, contact our helpful Sales Team on 020 8692 2255 or via our website.

Leave a comment